Roller shutters—sometimes called rolling shutters or simply rollers—are vertically operating door or window closures that coil around a drum situated above the opening. They are valued for their compact footprint, durability, and ability to combine security, weather protection, and light control in a single assembly. Modern roller shutters range from rugged industrial doors guarding warehouse docks to slender aluminum slats that disappear into a residential soffit. Regardless of scale, every roller shutter relies on the same core principles: a curtain of interlocking slats, side guides that channel the curtain’s movement, and an operating device that raises or lowers the assembly on demand. This article surveys the main design families and explains how today’s operating systems meet the rising expectations for safety and convenience in commercial and domestic settings.

The slatted curtain is the heart of any roller shutter, and its construction largely determines performance in terms of strength, thermal behavior, and aesthetics. Manufacturers typically group shutters into three broad categories[1].

Single‑wall slats, usually roll‑formed from galvanized steel or extruded from aluminum, provide a cost‑effective barrier against forced entry. Their simple profile makes them easy to repair, yet they offer limited insulation. They are common in storefronts, service counters, and industrial portals where temperature control is secondary.

Double‑wall slats sandwich a polyurethane or mineral‑wool core between two aluminum skins. The result is a lightweight curtain boasting thermal transmittance values as low as U = 1.4 W/m²·K, roughly a five‑fold improvement over uninsulated steel[2]. Homeowners choose these shutters to curb heat loss, reduce street noise, and achieve near‑blackout darkness for bedrooms or media rooms.

Some applications demand airflow or visibility. Perforated steel slats, open‑link grille sections, and clear polycarbonate panels let retailers display merchandise after closing while still deterring theft. At the other extreme, fire‑rated rolling curtains employ a double layer of interlocking steel and proprietary expansion joints to achieve up to four‑hour integrity in accordance with UL 10B and EN 1634‑1 listings[3].

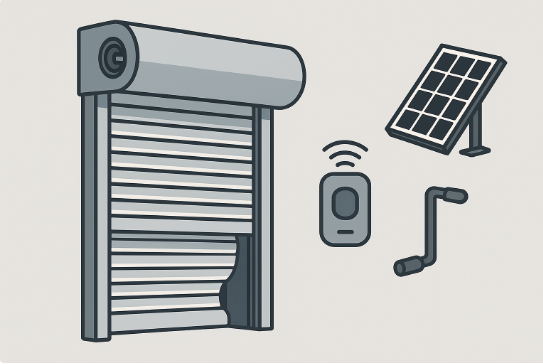

How a shutter opens matters as much as what it is made of. Operability influences user safety, daily convenience, and long‑term maintenance. Three drive families dominate today’s market[4].

In the simplest arrangement, a torsion spring within the barrel offsets the weight of the curtain so that an adult can lift or pull it down by hand. Spring‑balanced shutters thrive in kiosks and storage units that lack power. When the opening height exceeds about 3.5 m, a removable crank handle or geared chain hoist provides mechanical advantage. The absence of motors keeps installation cost low and reduces points of failure, but repeated manual cycling can be fatiguing on heavy doors.

Electric drive eclipsed manual mechanisms once compact tubular motors arrived in the late 1980s. Housed inside the barrel, a tubular motor raises or lowers the curtain at 8–17 rpm and integrates limit switches to stop travel precisely. Larger industrial shutters rely on outboard chain‑drive motors mounted beside the barrel; these deliver up to 1,000 N·m of torque and include a manual hand chain for emergency egress during power loss. Both styles now ship with obstacle detection that halts or reverses travel when the bottom bar meets resistance, reducing injury risk and slat damage.

Home‑automation hubs and energy codes have pushed manufacturers to offer low‑voltage drives paired with solar panels and lithium‑ion batteries. A daylight sensor can close shutters automatically on hot afternoons, trimming cooling loads by up to 25 percent in Mediterranean climates[5]. Voice assistants and smartphone apps further raise convenience—yet each connected feature introduces cybersecurity considerations now addressed by EN 303 645 and UL 2900‑1 guidelines.

Selecting a roller shutter extends beyond curtain profile and motor size. Effective design aligns the shutter’s wind load rating, guide depth, and locking method with site realities ranging from hurricane exposure to habitual vandalism. A coastal warehouse in Florida may require a shutter certified to withstand 80 m/s gusts and fitted with stainless‑steel bearings to resist corrosion. By contrast, an urban café values perforated aluminum slats that comply with municipal fire egress codes by disengaging under less than 150 N of upward force.

Routine maintenance chiefly concerns balance‑spring inspection, motor gearbox lubrication, and curtain alignment checks. Industry surveys reveal that neglected guide wear accounts for over 40 percent of premature shutter failures, underscoring the importance of semi‑annual service[1]. Predictive analytics are emerging: sensors embedded in the bottom bar transmit cycle counts and vibration signatures to a cloud dashboard, enabling planned part replacement before outages occur.

Finally, acoustic and thermal performance deserve attention. A properly sealed insulated shutter can cut external noise by up to 18 dB(A) and improve window U‑values enough to meet Passive House retrofit targets. To achieve these gains, installers must specify brush or rubber seals at both guide edges and ensure lintel pockets are insulated to prevent thermal bridging.

From single‑wall steel curtains guarding factory bays to app‑controlled, solar‑powered slats shading suburban bedrooms, roller shutters have diversified to meet evolving security, energy, and lifestyle demands. Curtain material dictates core strength and insulation, while the choice between manual, electric, or smart drives balances cost against convenience. Properly matched to site conditions and maintained with modest diligence, modern roller shutters deliver decades of reliable service—quietly coiling out of sight until duty calls.