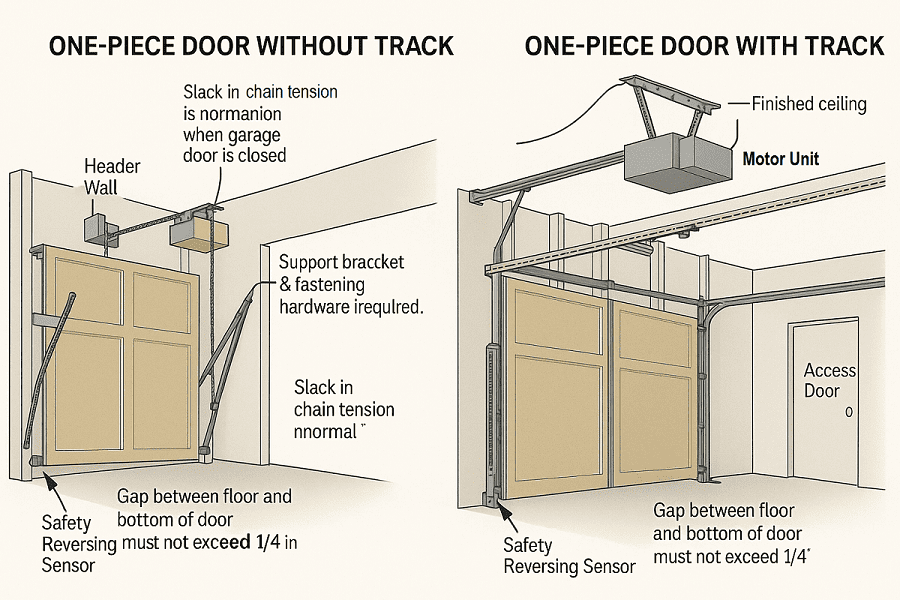

Single-panel (one-piece) garage doors are formed from a single, rigid leaf that pivots upward to clear the opening. Two installation methods dominate—jamb-type hinge hardware and one-piece track hardware—each creating a distinct motion path, clearance requirement, and load pattern.

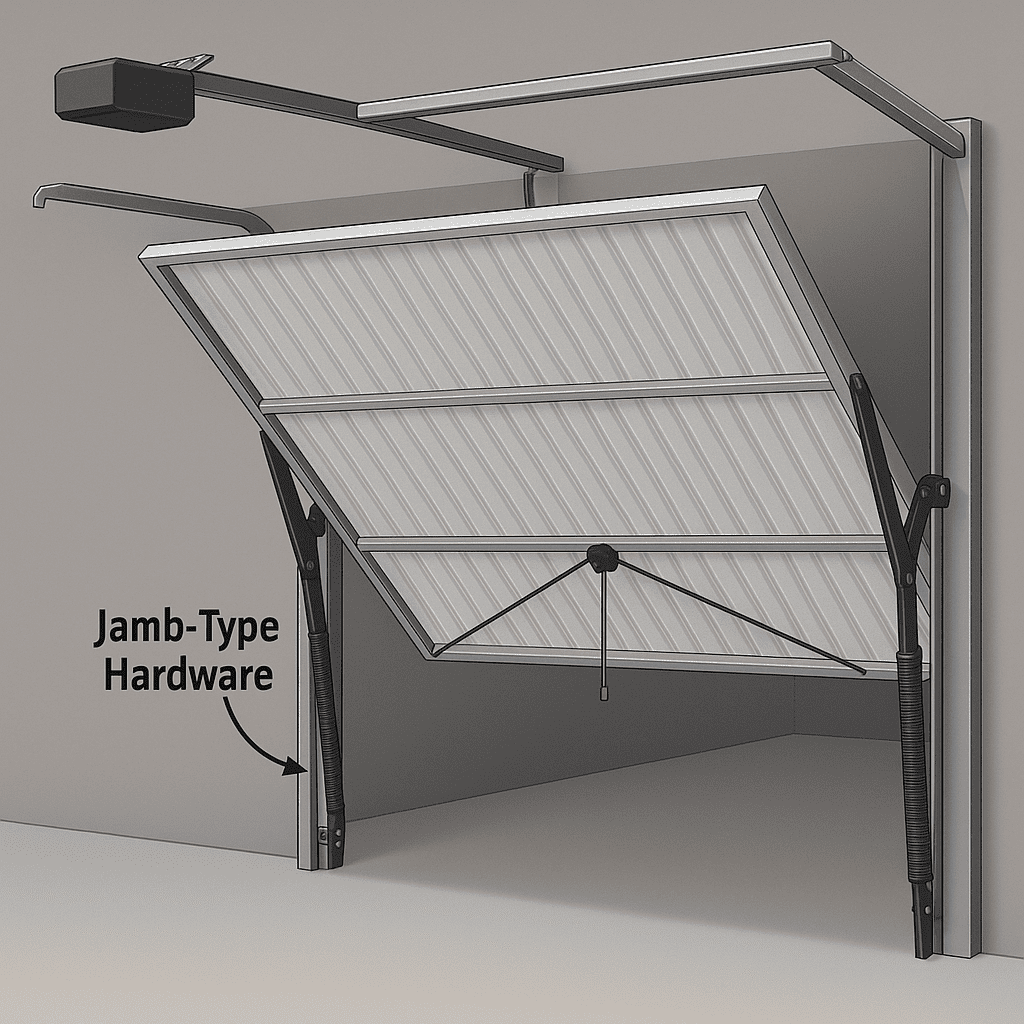

With jamb-type hardware, a heavy hinge (or unequal parallelogram hinge) is fixed near the mid-height of each jamb. As the door lifts, the panel follows a long outward arc before finishing above the header, placing the front third of its travel outside the wall plane.[1]

Historical note: Catalogs as early as 1902 show “float-over” one-piece doors using jamb pivots; by the 1920s these doors were common as America’s automobile boom created demand for affordable garages.[2]

Advantages

Disadvantages

Track hardware mounts a horizontal track atop each side jamb. Rollers at the panel’s top corners glide in these tracks while bottom hinges guide the lower edge. As the door retracts, the panel slides almost entirely inside the header, dramatically shortening the exterior sweep.[1]

Historical note: Steel-framed one-piece doors with retractable tracks gained popularity after World War II; firms such as Taylor Door (Detroit, 1946) promoted the design for its smoother action and compatibility with emerging electric operators.[2]

Advantages

Disadvantages

Both jamb-type and one-piece track systems preserve the clean look and budget-friendly simplicity of a monolithic door. Choose jamb hardware when period authenticity and minimal hardware are priorities—and ample forecourt space exists. Opt for track hardware where driveway clearance is tight, electric automation is desired, and framing can support the extra components. Either way, regular maintenance of springs, pivots, and tracks is essential for safe, smooth operation.