The “electric eye” — a simple light‑beam detector that stops a door when something breaks the beam — is now so common that most homeowners never think about it until the door refuses to close. Behind that familiar click‑and‑reverse lies nearly a century of engineering progress, regulation, and changing ideas about home safety. This article traces the first uses of electric‑eye technology, explains how the modern garage‑door photo‑sensor works, and looks at the new sensing platforms that may soon replace the humble infrared beam.

Photoelectric safety beams were already in use before the first overhead garage doors existed. In 1931 General Electric unveiled its Magic Eye in Cleveland, Ohio—an ultraviolet beam and relay that let hospital doors swing open without a touch. Over the next few years, similar light‑beam barriers migrated to packaging lines and shop‑entry alarms, showing the concept’s reliability, low cost and quick retrofit potential for electromechanical equipment. What the early devices still lacked was a large consumer market to push prices down; that opportunity finally arrived with the rise of automatic overhead garage doors.

From Push‑Button Convenience to Safety Feature

C. G. Johnson introduced the first electric overhead garage‑door opener in Hartford City, Indiana, in 1926. Early openers offered little beyond convenience: a wall switch or, after World War II, a bulky radio transmitter that lifted the door on command. By the mid‑1950s companies such as Genie and LiftMaster were advertising radio‑controlled systems that also touted an “invisible light beam” able to halt the door if a car or child crossed the threshold [1]. These first garage‑door electric eyes were optional upgrades, using incandescent lamps or cadmium‑sulfide cells mounted roughly 11.8 inch above the floor. Reliability was modest; vibration and sunlight often caused false trips, and many homeowners simply disabled them.

The Safety Imperative

During the 1960s and 70s the garages of rapidly growing suburbs became both storage rooms and play spaces. Reports of entrapment injuries — particularly to small children — began to surface. Consumer‑safety advocates pressed for standards that would force manufacturers to include redundant protection. Industry research showed that a properly aligned photo‑eye, placed low enough to detect a toddler, prevented nearly all closing‑door accidents [2]. Yet adoption remained voluntary, and surveys in the early 1980s found that fewer than one‑third of U.S. residential openers shipped with working sensors.

Regulatory Milestones

The turning point came when the U.S. Consumer Product Safety Commission worked with Underwriters Laboratories to update UL 325, the primary standard for door operators. The 1988 edition required any opener made after 1 January 1991 to reverse upon hitting an obstruction. A further revision, effective 1 January 1993, demanded a second, non‑contact entrapment‑protection device, and the infrared electric eye was the least costly way to comply [3]. The Federal Register incorporated the change, making UL 325 effectively federal law for residential products [4]. Within two years, every major North‑American manufacturer shipped photo‑eye pairs as standard hardware, and retro‑fit kits were offered for older units.

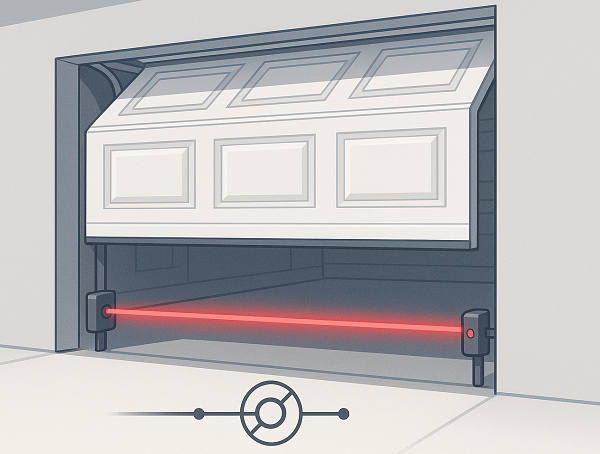

Today’s garage‑door electric eye is a matched transmitter–receiver pair housed in weather‑resistant plastic. The transmitter drives an infrared light‑emitting diode, pulsed at 30–60 kHz to distinguish the beam from ambient light. A simple lens narrows the beam to a few degrees, while a visible‑light LED gives installers instant feedback on alignment. The receiver contains a phototransistor tuned by an optical filter and an active band‑pass amplifier. When the beam is intact, the receiver sends a low‑voltage logic signal to the opener’s microcontroller. If the beam is interrupted for more than about 10 milliseconds, the controller stops the motor and commands a full upward travel. Because the circuit is failsafe — any broken wire, dirty lens, or misalignment also opens the circuit — the door cannot close unless the system is healthy.

Several additional design details raise reliability:

• Automatic gain control to maintain sensitivity in bright sunlight.

• Digital checksum packets so adjacent garage doors do not interfere.

• Self‑test pulses every cycle; if either eye fails, the opener shows an error code.

These refinements mean a typical sensor set now costs under 40 USD yet survives 100 000 operating cycles with less than 0.5 % false‑trip rate.

Although the infrared photo‑eye meets today’s safety rules, researchers and manufacturers are exploring replacements that promise richer information and easier installation.

Depth‑imaging arrays. Low‑cost time‑of‑flight (ToF) chips can map an entire doorway in 3‑D, spotting obstructions anywhere within the opening instead of only at beam height. Pilot installations on commercial shutters show fewer alignment issues and rapid self‑calibration.

Millimetre‑wave radar. Short‑range 60 GHz radar modules, originally developed for automotive blind‑spot detection, can detect motion through light fog and dust. A single module mounted near the header could eliminate floor wiring altogether.

Computer vision. High‑dynamic‑range cameras coupled to on‑board neural processors recognise people, pets, and vehicles. Vision systems can also read QR‑codes on delivery packages, granting temporary access and logging events for insurance claims.

Multimodal sensor fusion. UL 325 already allows edge sensors or constant‑pressure systems as equivalents to an electric eye. Future editions may certify combined ToF + pressure mats, or camera + radar packages that continue to function even if one modality fails. Universal‑design researchers note that such redundancy also assists users with limited mobility, who may need longer dwell times before the door closes [7].

Greater intelligence brings new concerns. Connected openers upload video clips, leading to debates about data ownership and firmware locks. Cases such as Chamberlain v. Skylink show how manufacturers sometimes use digital‑rights claims to restrict third‑party accessories [8]. Regulators must balance safety, competition, and privacy while updating test procedures for technologies that do more than simply break a light beam.

Cyber‑security is another priority: a compromised cloud‑linked opener could expose a home to intrusion or denial‑of‑service lockout. The forthcoming fourth edition of UL 325 is expected to incorporate secure‑boot and signed‑update requirements similar to those adopted in the elevator industry.

Environmental resilience also matters. Infrared eyes can be shielded from sun and rain, but cameras and radar modules must operate across –30 °C to +50 °C, resist power surges from lightning, and survive occasional impact from bicycles or lawn tools. Engineers are experimenting with conformal coatings, reinforced brackets, and modular replacement cartridges to keep maintenance simple.

From GE’s ultraviolet “Magic Eye” of 1931 to the smart, networked sensors under discussion today, the electric eye for garage‑door openers illustrates how a single safety concept can evolve through invention, regulation, and integration with broader technological trends. Infrared photo‑eyes will remain ubiquitous for years, but the path is clear toward multi‑sensor platforms that not only prevent entrapment but also verify deliveries, monitor energy usage, and interface with whole‑home automation. As new standards emerge and component costs fall, tomorrow’s garage door may rely on digital vision or radar — yet the core idea pioneered nearly a century ago will still be at work: stop the door when something is in the way.

List of literature

Tekla S. Perry. “The Consumer Electronics Hall of Fame: LiftMaster Garage Door Opener.” IEEE Spectrum, 2019.

John D. Wagner. “Garage Doors.” Chief Architect Magazine, 2008.

Door & Access Systems Manufacturers Association. UL 325 50th Anniversary Report, 2023.

U.S. Consumer Product Safety Commission. Safety Standard for Automatic Residential Garage Door Operators, Federal Register, 13 July 2018.

Wolfgang F. E. Preiser and Korydon H. Smith. Universal Design Handbook. 2nd ed., McGraw‑Hill, 2012.

Aaron Perzanowski and Jason Schultz. The End of Ownership: Personal Property in the Digital Economy. MIT Press, 2016.